Home

>>

Aluminum acoustic Panel

>>

Aluminum Foam Acoustic Panel

Aluminum Foam Acoustic Panel

PRODUCT INFORMATION

Introduction

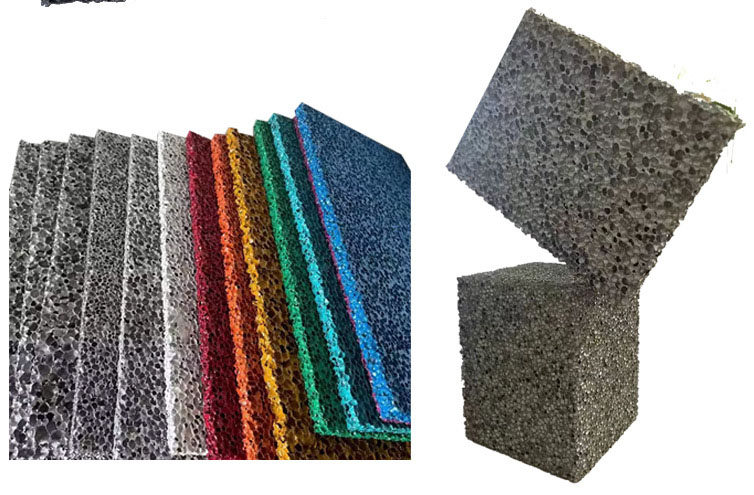

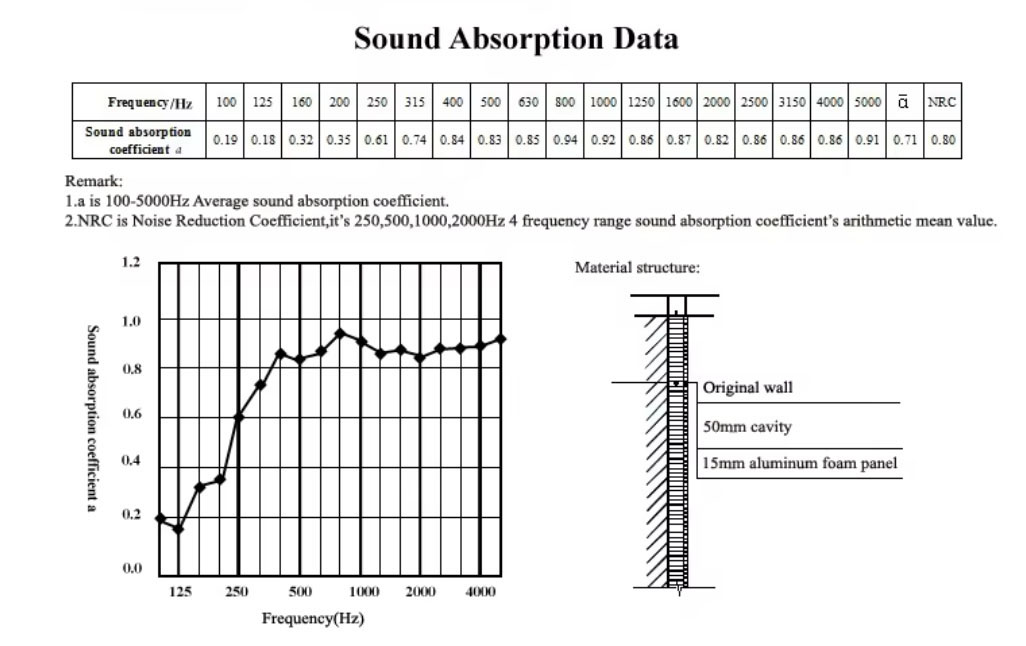

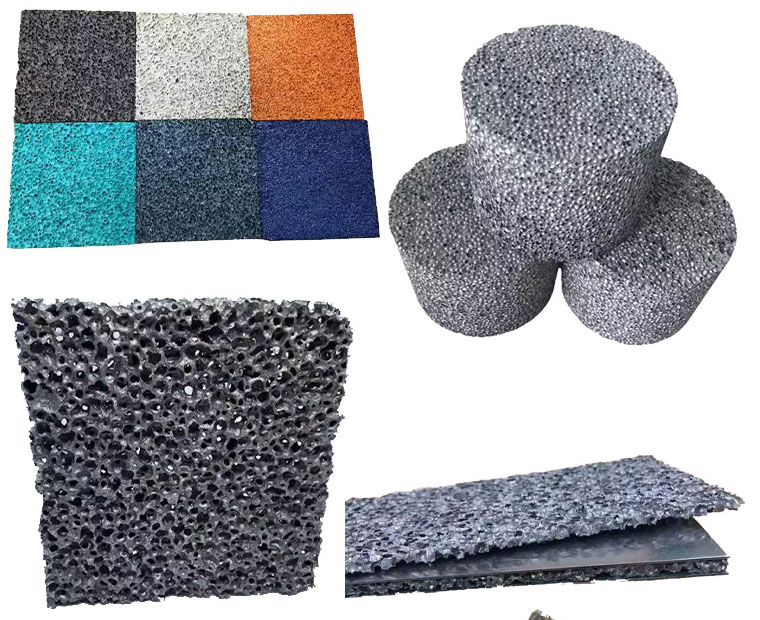

Aluminum foam sound-absorbing board has a comprehensive noise reduction coefficient of 0.75, and the sound absorption coefficient in the mid-frequency range of 250~1000Hz is more than 0.9, which is far more than the common sound-absorbing materials, such as rock wool, gypsum board and perforated metal board. Its comprehensive sound insulation and noise reduction capacity is polyurethane foam, glass fiber, honeycomb aluminum 7-10 times, applied to high-speed trains, automobile trunk panels when the sound insulation capacity is close to 30dB. aluminum foam material with its superior acoustic noise reduction and related performance is used in more and more fields, mainly focused on road sound barriers, road tunnel noise reduction, undersea tunnel noise reduction and tunnel ventilation; swimming pool acoustic wall; aluminum foam Sound-absorbing panels are used to make sound-absorbing linings for buildings, such as recording studios, dubbing rooms, concert halls, conference halls, gymnasiums and so on.

Foam aluminum acoustic panel acoustic noise reduction effect of the main influencing factors are as follows:

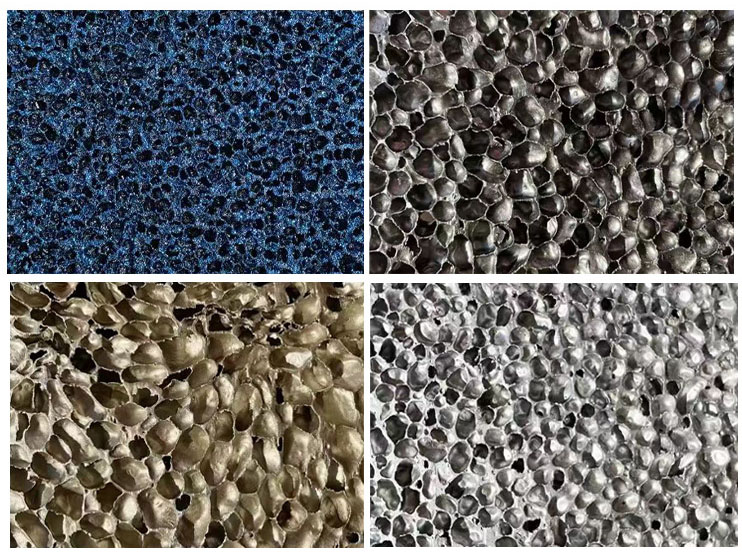

1. Aluminum foam acoustic panel is a porous material, the sound absorption performance of high-frequency sound is obvious, that is to say, in the high-frequency sound absorption coefficient is large. And the sound absorption effect of low-frequency sound is not ideal, so the sound absorption coefficient is small in the low-frequency region.

2. Foam aluminum sound-absorbing panels sound-absorbing panels of different thicknesses, sound-absorbing frequencies are different. With the increase of thickness, the excellent sound absorption frequency will be in the direction of absorbing low frequency. However, when the sound frequency is greater than 500Hz, the sound absorption coefficient of aluminum foam acoustic panel has nothing to do with the thickness.

3. When the density of the foam aluminum acoustic panel increases, at this time the excellent sound absorption frequency will also be to the development of low-frequency sound, foam aluminum acoustic panel aperture size and number of acoustic panels on the acoustic performance of the acoustic panels have significantly different performance.

Simply put, different choices of foam aluminum acoustic panels, such as thickness, density, porosity, etc.. will have different sound absorption effect. Regardless of how to choose the foam aluminum acoustic panels, fit their own situation is more effective.

Foam aluminum sound-absorbing panels in the construction industry is also increasing the scale of application;.

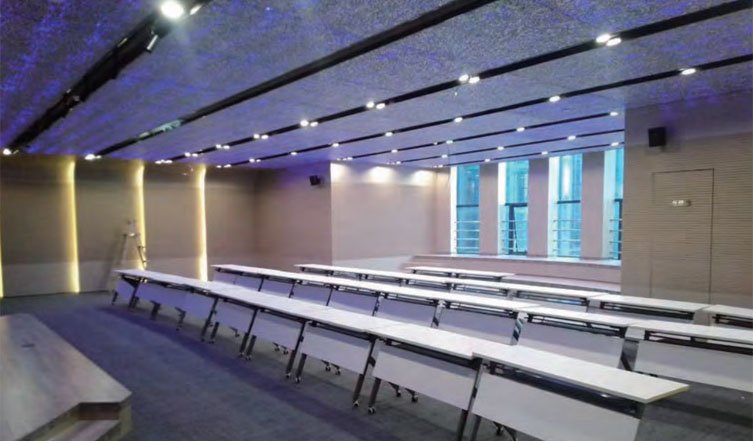

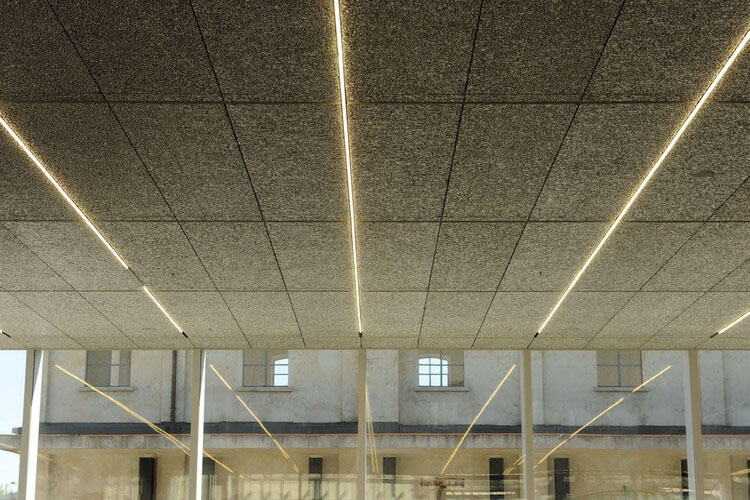

1. Making sound-absorbing linings for buildings: such as various gymnasiums, recording studios, dubbing rooms, concert halls, conference halls and so on.

2. Swimming pool sound-absorbing wall: solving the problem that the sound-absorbing material greatly reduces the sound-absorbing ability after absorbing water. The sound-absorbing board made of foam aluminum sound-absorbing board has a high sound-absorbing rate, and its sound-absorbing function is not reduced in a humid environment.

3. Foam aluminum sound-absorbing panels made of high-rise building curtain wall: rigidity of more than 15Mpa, energy absorption, sound insulation, heat insulation and other properties, inside and outside the coefficient of thermal expansion is consistent to ensure that the leveling, non-combustible, good fire resistance. Compared with solid marble board, weight reduction of 2/3, impact toughness increased by more than 2 times.

4. Do soundproof floor: building soundproof is a problem. The use of 5 mm thick planks, 10 ~ 15 mm thick foam aluminum composite flooring, floor spacing in more than 20 dB.

5. Interior decoration of KTV and other places: the sound-absorbing panels made of aluminum foam are used to decorate the ceiling and walls of KTV and other entertainment places with sound-absorbing decorations, which have good noise reduction effect, are non-combustible and have good fireproofing performance.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|