Acoustical Foam

กก

Acoustic foam - you should know that!

It is important for you to know what makes a good acoustic foam so that

you will not be misled by the many offers on the Internet.

Because unfortunately, a lot of practical jokes are driven in this area

and we experience it again and again that here often wrong advice is

given or in the

product descriptions untrue statements are made. Once

assembled, you can not return the foam and you may have to live with the

result, even if it would have

been better solved with other materials.

Take five minutes to find out how to differentiate between a good and a

bad acoustic foam, or where to choose a cheaper foam over a more

expensive acoustic foam.

And you'll also learn how foams help improve

the sound or how you can effectively insulate walls.

What is an "acoustic foam"?

The word "acoustic foam" is in the strict sense an invention of the

industry - because a foam pad or a mattress has an acoustic effect, due

to the open-pore nature of the foam.

With these types of foam, which are

designed as upholstery, but you can solve acoustic problems not

targeted, i. you do not know what the result will look like in the end.

There are no measurement tables with frequencies or the like and also no

experience, with which one can exchange in forums,

because you will

hardly find anyone who moved a mattress in the recording studio on the

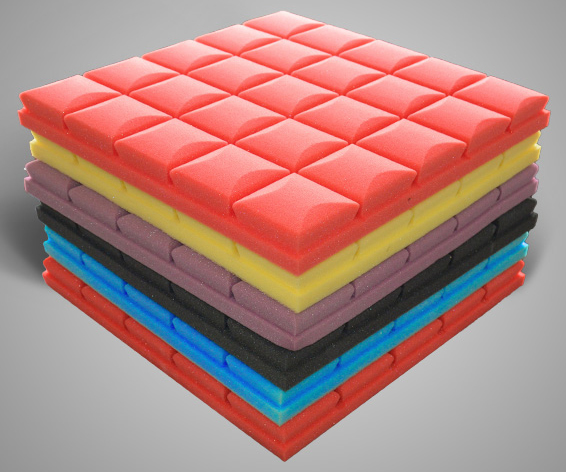

walls. Acoustic foams are foams specially designed for the acoustic

sector,

with different surface finishes, plate thicknesses, weights,

pores, colors and profile ground conditions. Depending on the acoustic

problem case,

proven foams are used or are recommended, with which one

can solve the problem purposefully.

There are two basic acoustic applications: Hall reduction within rooms

or sound insulation or noise insulation between rooms, ie the prevention

of sound passing

through solid surfaces, e.g. in a soundproof apartment

or a soundproof waiting room or office (and also in the technical field

in the insulation of machinery,

compressors, etc.). This is referred to

as sound attenuation (within a room) and sound insulation (between two

rooms, for example).

Click on Difference of sound attenuation and sound

insulation for exact details.

Which acoustic foam do I need for my problem?

If you want to reduce the reverb in your room:

... you need e.g. Puff foams or pyramid foams (with these profiled

foams, however, they only reduce higher frequencies) or even better flat

absorbers without profiling,

which absorb sound over all frequencies and

also act in the low frequency range. Pimples and pyramids are therefore

often found in recording studios or music rooms,

if you only want to

eliminate certain frequencies. Plane absorbers, on the other hand, are

best used in areas where you want to absorb as much as possible.

in the

office, restaurant, waiting room, bowling alley, kindergarten, schools,

universities etc.

Absorbers will always absorb significantly more in comparable plate

thickness than equally strong dimpled or pyramid foams.

It is also

important to pay attention to the fire protection of the acoustic foams,

which you must or want to meet on site. We carry different products with

different fire protection levels. Our Basotect acoustic foam here has

e.g. the highest standard and may i.d.R. be used everywhere (in case of

doubt, always check on-site).

All of these products can be found above.

It is a misconception that you need profiled surfaces to dampen noise.

The plate thickness is crucial and not the surface area of the

individual plates, as many claim.

This is clearly proven by

measurements. Many confuse the surface of a panel with the overall

surface of a room in m²! Of course,

the total surface area has an

important influence on the overall absorption. The more misplaced, the

less reverb you have.

In addition to these classic profiled or non-profiled plates, there are

still specialists such. Bass absorbers or broadband absorbers that

absorb

especially in the low-frequency range. And of course you do not

necessarily have to take rectangular plates to reduce the reverb - you

can also use circles,

ovals, stars or other shapes. Only the panel

thickness and the number of total absorbing surface on the ceiling in m²

are decisive. Furthermore,

we also carry acoustic images or ceiling

panels and partitions, for the office area. In our online consultant you

will find many standard problems with

our recommendation of products,

number, plate thicknesses etc ..

If you want to effectively dampen noise ....

Then you will not get far with bubble foam or pyramid foam. Also in the

field of insulation falsely pyramid foam or nub foam is recommended

again, although they can work, but in comparison to more suitable

materials have a downright ridiculous effect. To insulate properly -

whether a room wall, a machine or engine - you need plane absorber with

high weight. Because only mass and plate thickness will effectively

prevent the sound waves from propagating or penetrating walls.

This area is covered by e.g. our products in the category sound

insulation. Here you will find massive acoustic foams, such as our very

popular composite foam in various thicknesses as well as other

supporting materials such as bitumen foil or bitumen board, which

additionally dampen the noise or deceive metal surfaces. Details can be

found there if you need effective insulation. And we produced our

in-house wall insulation kit, which effectively insulates walls later

(for example to the neighbor).

How do I recognize the quality of a foam?

Not only on the product description, but also in the case of reputable

suppliers. Sounds strange, but it is. All traders boil only with water

and the basic ingredients e.g. with PU foam nunmal are the same

worldwide. You can cheaply produce and foam the puff foam or pyramid

foam of the same name or you can use high-quality foam with

higher-quality foam or you can thin the bottom of profiled foams and cut

the pyramids and nubs very high - saves material, but then significantly

reduces the effect.

The problem is - in both cases it means in sales then "bubble foam" or

"pyramid foam", etc. You can assume that absolute low prices that are

far away from the average price, even with almost 100% guarantee, are

bad foams that will not be of much use to you acoustically - or a trader

sells or closes and lowers the prices and you have if necessary a real

opportunity. Unfortunately, there is the other case: some traders charge

for a bad or mediocre foam an exorbitant price - this can e.g. be due to

the storage costs, which the dealer has or because he is not specialized

or no large volume converts and next to foam still flowers and postcards

sold or foam as a marginal product and few sales at a high price are

sufficient.

For this reason we usually offer different qualities for the most common

acoustic foams. Our solid Eco quality (cheap but not cheap!), Our very

high quality MicroPor quality with very fine pores and very good

absorption and also flame retardant equipped and our high-end product of

Basotect, which absorbs excellent, is flame retardant and does not

yellow.

Foam storage - the expert in "acoustic foams"

If our selection "kills" you best use our large online consultant - many

topics are already described very accurately and appropriate acoustic

foam recommended. You can then order these directly online from us. We

not only have the largest selection, but also low prices and fast

delivery from stock - almost all materials that you can find in our shop

are also available in larger quantities. Note the delivery status

display for the articles. Order your acoustic foam with just a few

clicks directly from us. And as with all materials in our shop, we

manufacture our foams completely in Germany - from the foaming of the

acoustic foams to the final cut - this guarantees a high quality, long

life, best absorption and an environmentally friendly manufacturing

process. Quality "Made in Germany".

More information about our acoustic foams can be found in our foam blog

- Topic: Acoustic foam and our complete foam program can be found on the

start page.

.

Free

กก

กก